Germany

Benthin Technology GmbH

Osterstader Str. 16

D-27572 Bremerhaven

T +49 (0) 471 79 84 190

F +49 (0) 471 79 84 3 190

info-technology@benthin.com

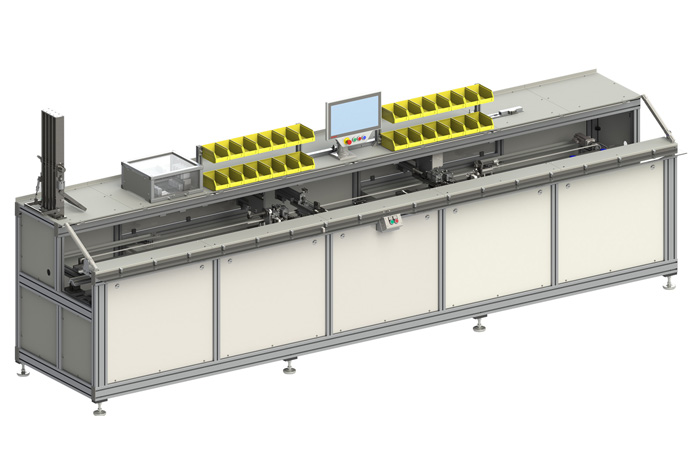

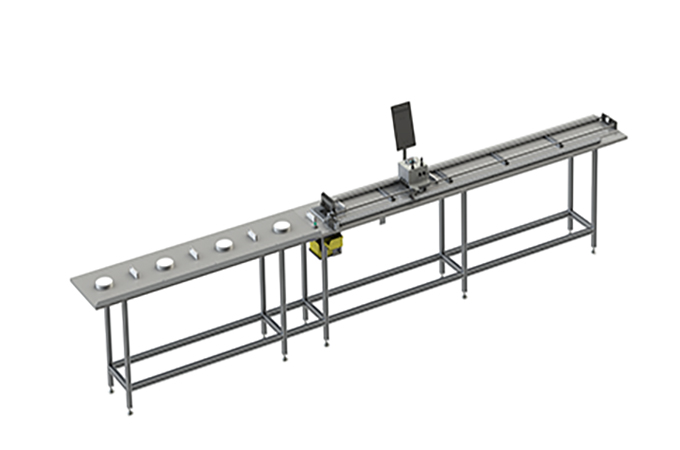

Plissee Fädeleinheit für das vollautomatische Fädeln von Benthin Plissee und Wabenstoffanlagen mit anschl. maschinenunterstützter und geleiteter Endmontage.

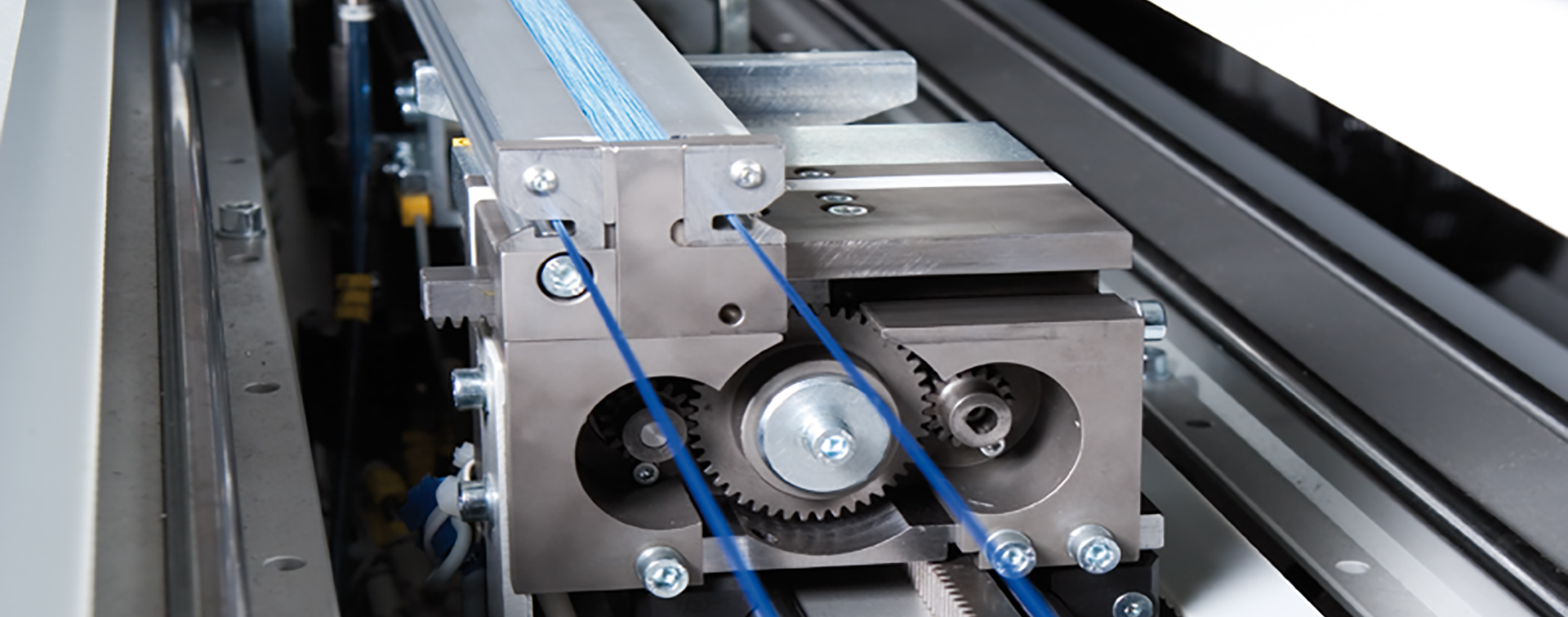

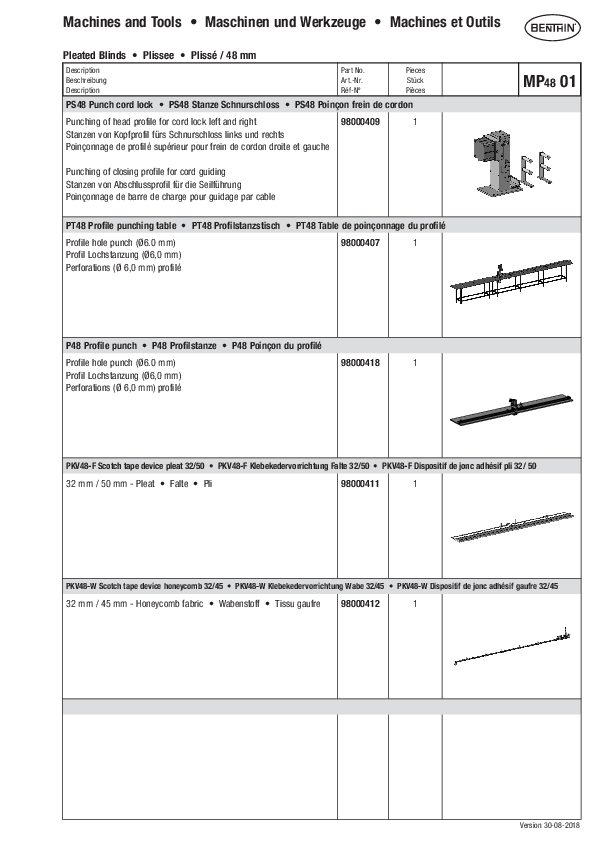

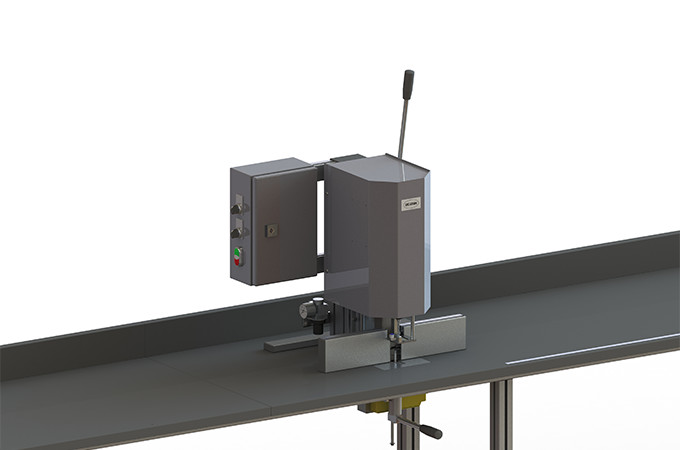

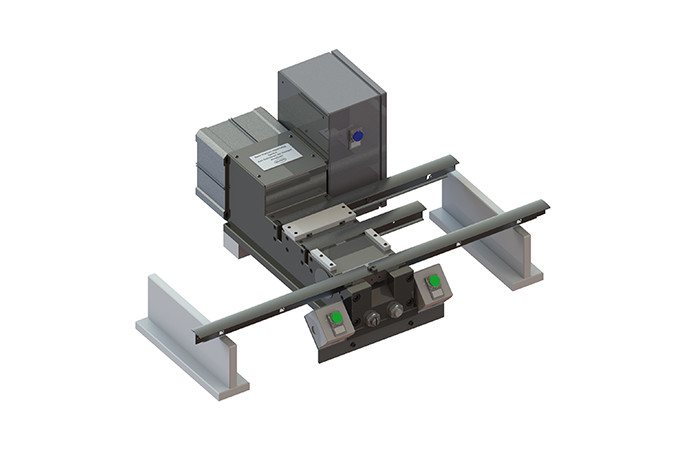

Plissee Schienenbearbeitungmodul

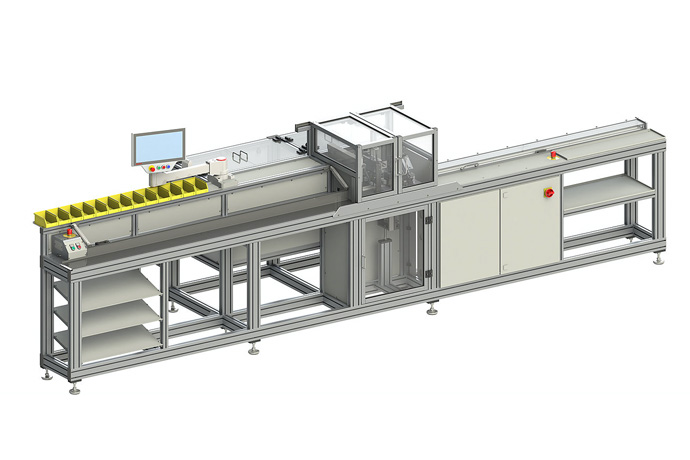

Pleated blind material drill & self-adhesive spline machine for automatic drilling of pleated and honeycomb blind fabrics and for the attachment of self-adhesive splines to the fabric package.

Pleated blind material drill & self-adhesive spline machine for automatic drilling of pleated and honeycomb blind fabrics and for the attachment of self-adhesive splines to the fabric package.

The PDM 850 boasts a speed regulator for stepless adjustment of the drill speed.

Drilling standard and honeycomb fabrics for pleated blinds up to a maximum stack height of 40 mm and a fold depth of 20 mm to 26 mm.

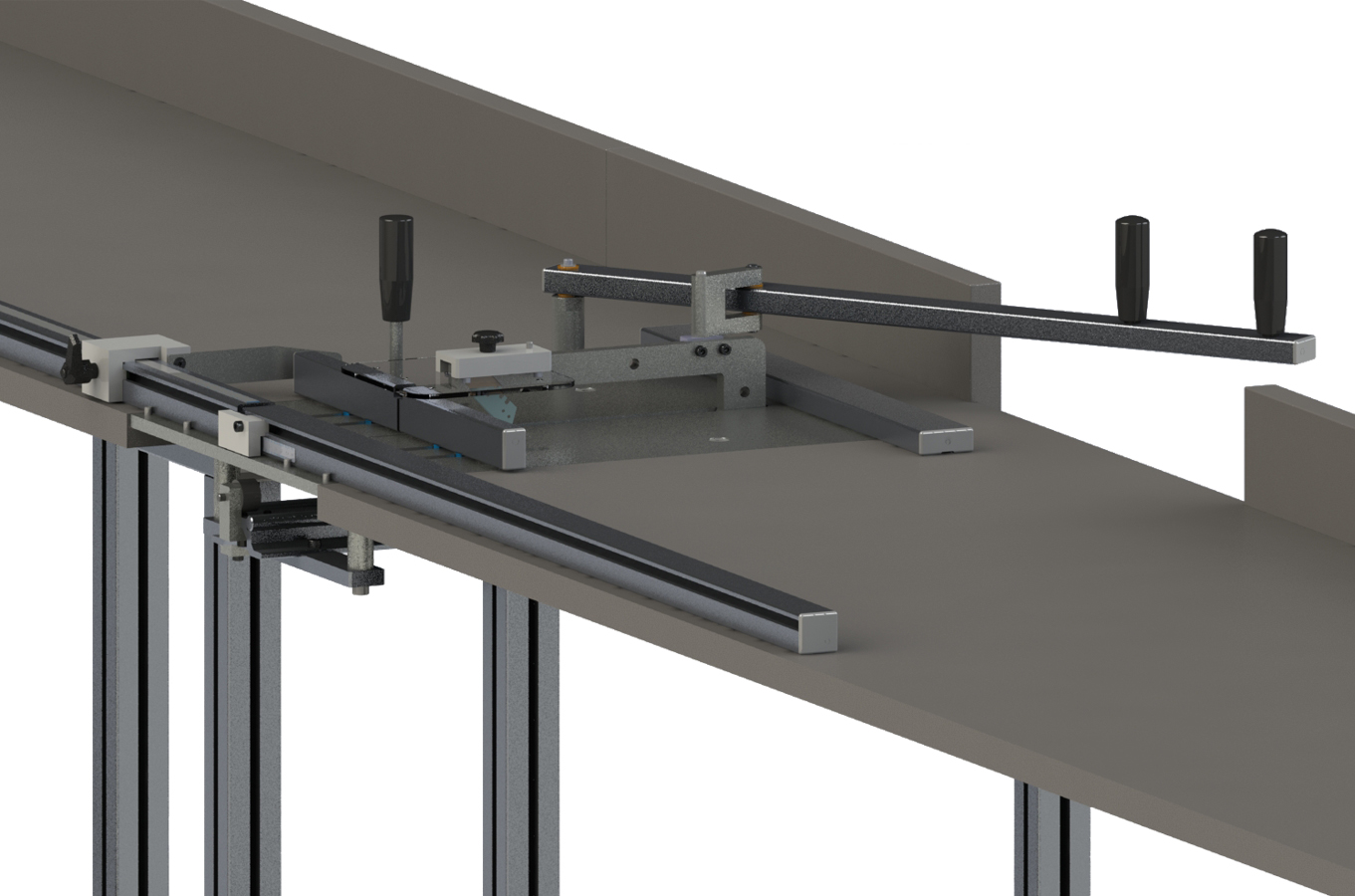

Exact cutting of pleated fabric.

Manual cutting of curtain-width pleated fabrics and honeycomb fabrics.

Manual cutting of curtain-width pleated fabrics and honeycomb fabrics.

Testing of verticals, rollers, venetians, assembly and function test of special pleated blind systems.

Controlled cutting and welding of pull chains and cords as ball welding or cord welding.

Accurate cutting of non-stretch cords to any desired length for a wide range of application.

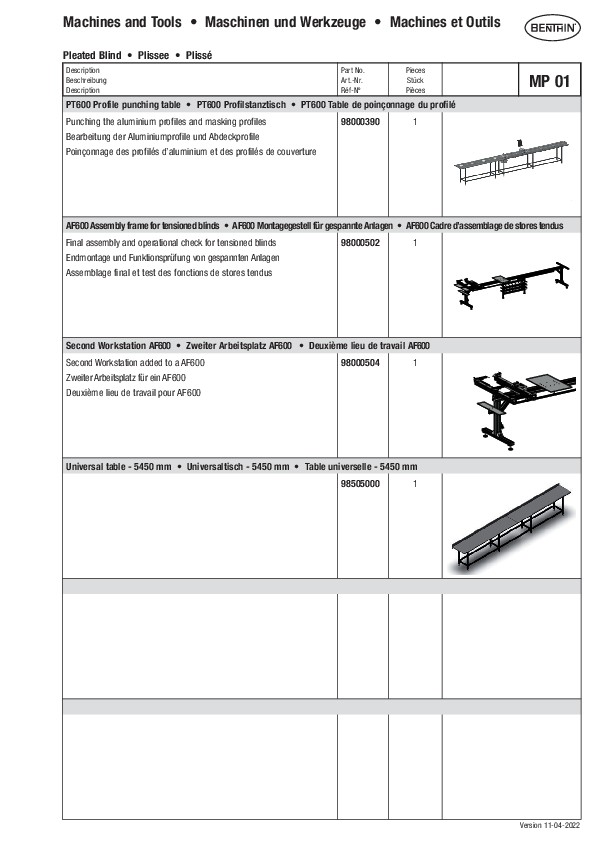

Final assembly and function test of tensioned pleated blinds.

Complete assembly of various types tensioned blinds and cord lock units.

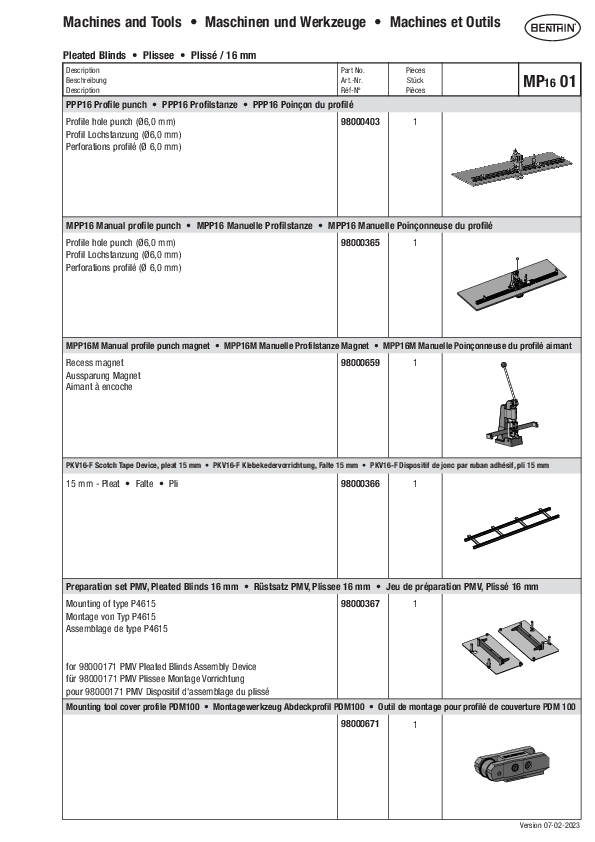

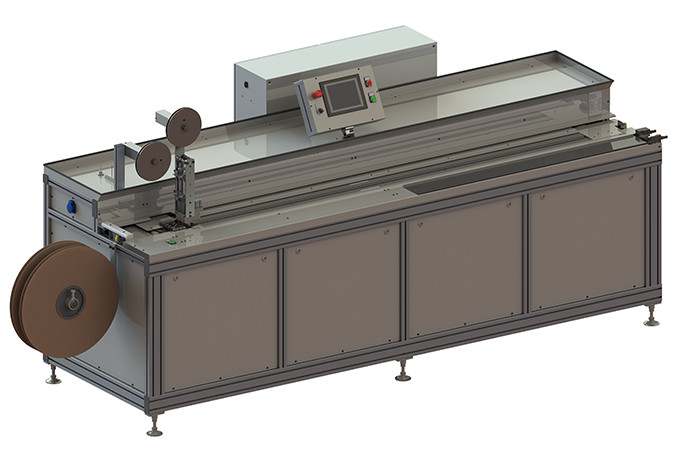

A device for punching holes in the pleated blind profiles for placing the cord lug, cord winder and chain drive.

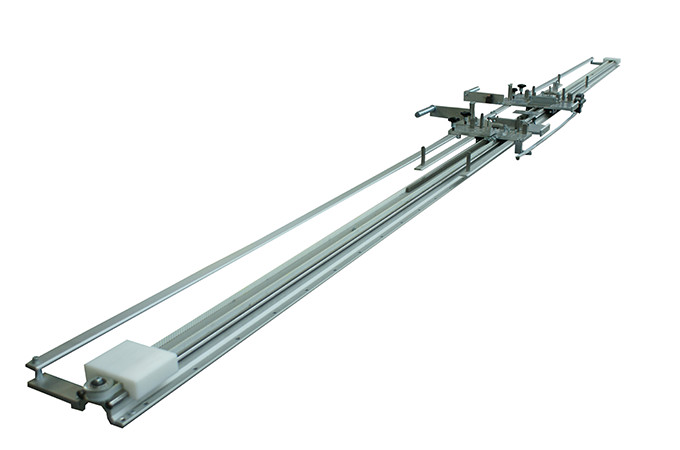

Fabric processing table for sticking adhesive strip to fabric stack quickly and accurately, then drilling the stack.

Preparing slope joints when using honeycomb fabrics.

Roof window profile punch for preparing roof window profile for installation on all current roof windows.

Quick, easy and clean cutting of the pleats of pleated honeycomb fabrics.