Germany

Benthin Technology GmbH

Osterstader Str. 16

D-27572 Bremerhaven

T +49 (0) 471 79 84 190

F +49 (0) 471 79 84 3 190

info-technology@benthin.com

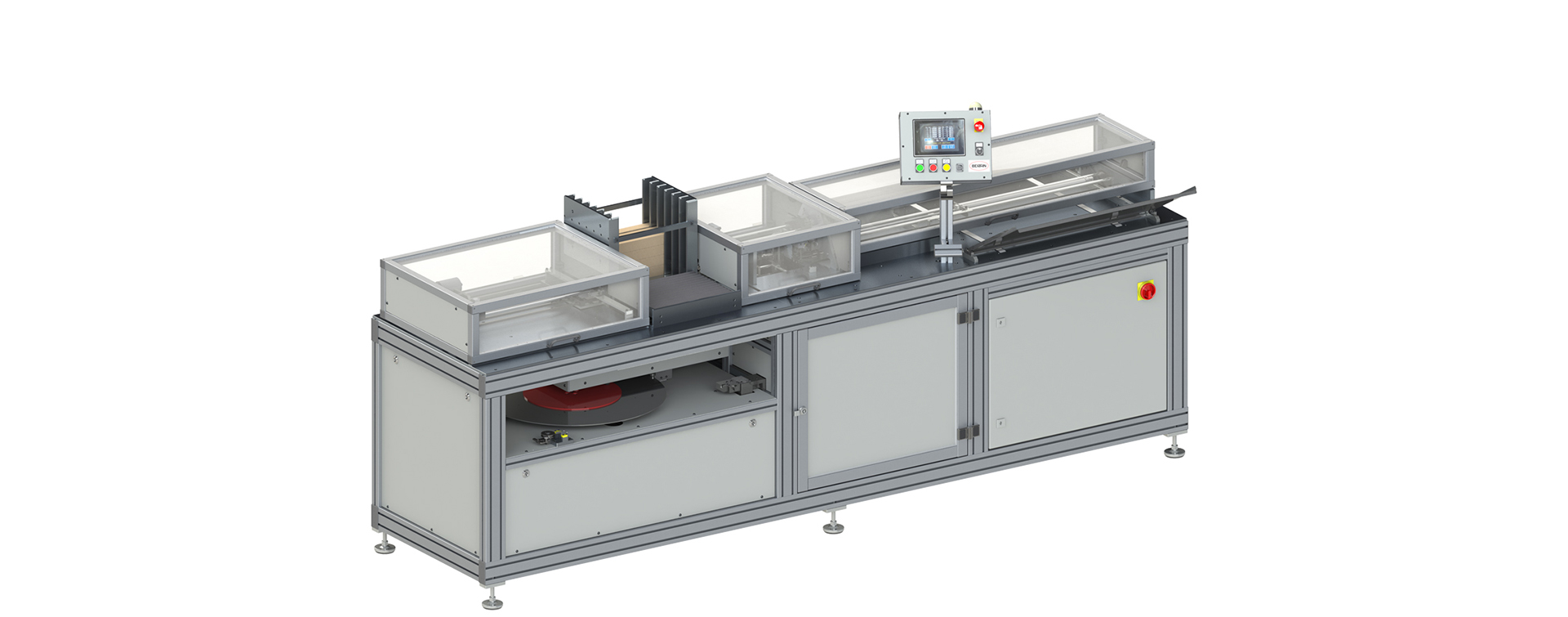

CT 2000 Carrier train automat

Fully automated fabrication of carrier trains to specified size for every vertical blind type.

- Article: 96235000

- Assembly of spacers made of spacer tape with carriers stored in cardboard tubes. Immediate deposit of the carrier trains in empty storage tracks.

- 6 storages are available at the machine to receive the carrier cardboard tubes. Instantly changing on: standard carriers, slope or spring carriers, other colours. Split draw trains can also be made.

- Production about 800 carriers per hour.

- Data entry by barcode scanner or manual by touch-screen.

- Taking away of filled storage tracks from the assembling. Ready for the following manual assembly at the track fabrication table.

- Options: Wireless bar code scanner. Modem for Tele-Service.

- Technical Specifications:

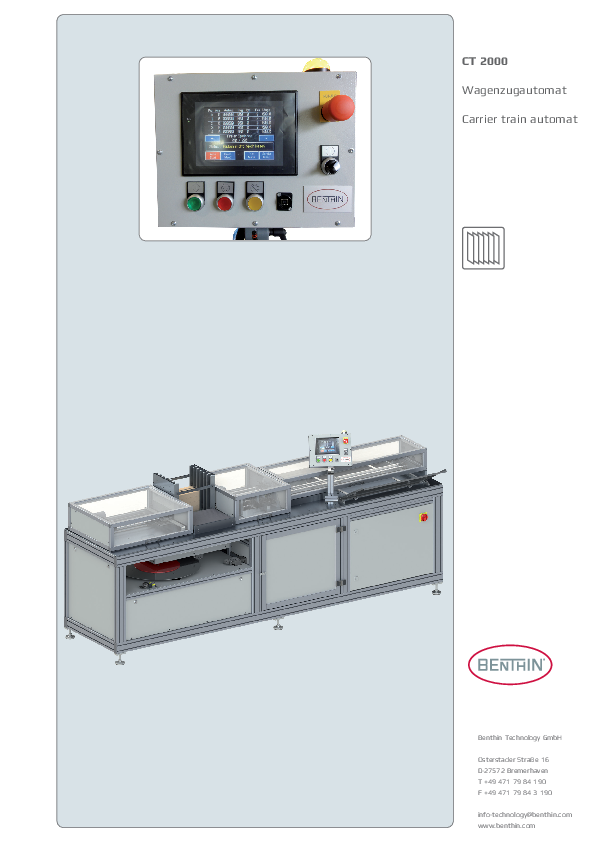

- Control: stored program control (SPC)

- Drive: precise servo motor for regulated spacer length

- Connection: pneumatic 7.5 bar, 5,4 qm/h, electrical 230 V / 50/60 Hz, 500 W

- Dimensions: 1285 mm x 3140 mm x 750 mm (H x W x D)

- Weight: 860 kg

- Material requirements: spacer tape, carriers

- Warranty: 12 months